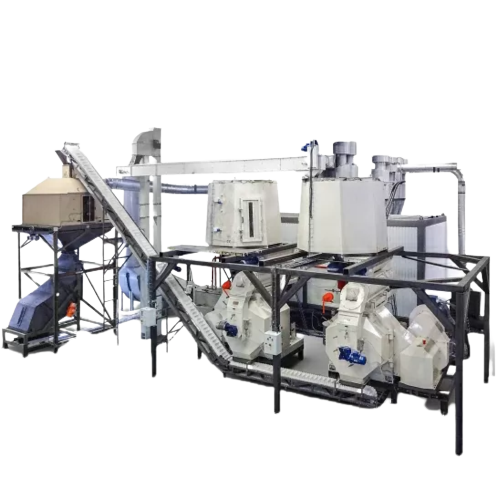

PELETON-4000 MT wet sawdust pellet production line is a high-quality equipment that can be perfectly adapted to your farm’s needs. The initial moisture content of the raw material should be up to 60%. There is also a solution to process sawdust with higher moisture content. Call us and ask about it.

Our dies, rollers, spare parts are made in Poland! Also, the cabinets and all the electrics are top of the line, also made in Poland while most of our competitors use Chinese cheap and unreliable substitutes! We focus on quality from the very beginning. Don’t skimp on security and bet on long-term cooperation with us.

What is included in the line ?

- LDG-4000 pellet production line

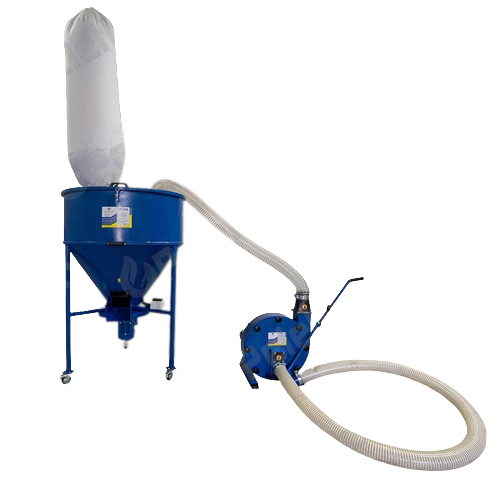

- SA-600 aerodynamic dryer

- Belt conveyor PT-1000 with fans

The composition of the PELETON 4000 MT pellet production line:

- The raw material is fed via a feeder with an enlarged buffer, into the SA-600 dryer. The aerodynamic dryer consists of a heat generator. Standard equipment includes a stove with a chamotte brick. The stove is fueled by ordinary wood. Furnace capacity 0.7 MW. It is possible to install a pellet burner PELETRON-250. The length of the pipeline is 25 m. The layout of the pipeline can be modified so that the wet sawdust pellet line takes up as little space as possible.

- The dried raw material is separated from the hot air by means of a cyclone. The sawdust goes into the screw feeder, and the hot air along with the steam is discharged through a chimney to the outside of the room.

- Using a screw feeder, the raw material is fed into the PELETON-400 pelletizer. The feeding of raw material is regulated by a potentiometer. Designed for processing hard raw materials, the pelletizer handles coniferous and deciduous sawdust without problems.

- The already finished pellet then enters the drum of the PB-100 calibrator, which is used to sift the pellet from dust and fines. It also serves the function of cooling the finished product.

- It is also possible to install conveyor belts, weigh-packing machine and sealing machine

Feel free to check out our other ads posted on the Peletto website. Call our specialist and schedule a free consultation to select the perfect machine for your farm’s needs. Visit us at our demonstration hall in Poznań and see our entire machinery live.

The content of this announcement is for information purposes only and does not constitute a commercial offer within the meaning of the Civil Code and other laws.

The content of this announcement is not a commercial offer under the Civil Code. To make a purchase, contact the merchant, confirm the price and delivery date.

tel. 889 899 914

tel. 889 899 904