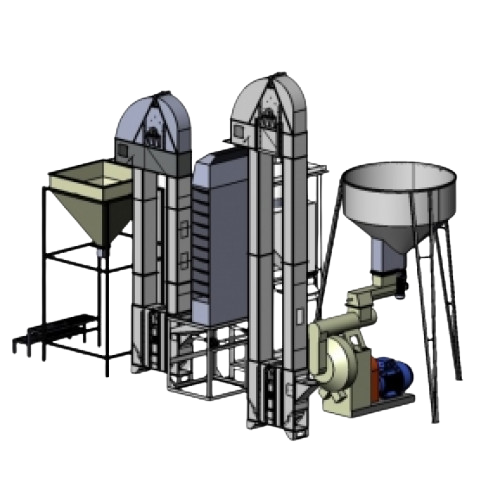

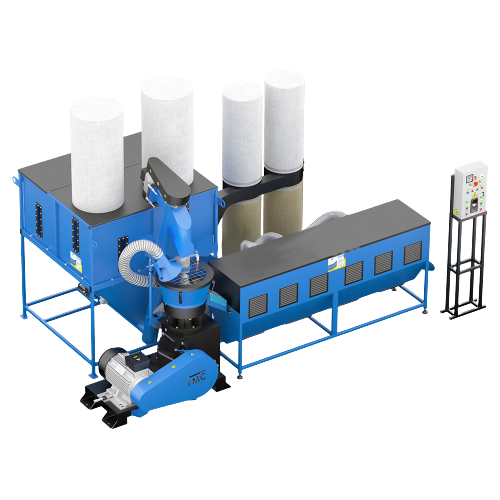

Peletto’s OGM-1.5 pellet / pelleted feed production line processes raw materials such as sawdust, wood chips, sunflower hulls, corn and grain production waste, straw and other biomass, among others. Impressive performance and ease of use make this complex versatile.

Investing in a professional pellet production line is a good solution for uncertain times. In an era of more expensive fuel and restrictions on burning coal or eco-pea, pellets as a renewable fuel are gaining in popularity.

Complete pellet production line with a capacity of 1.5 t/h

The fuel pellets produced on the OGM 1.5 complex meet all EU standards. The capacity of the line with one OGM 1.5 granulator is 1 ton/hour.

The line can be operated by 2 or 3 people.

Overall dimensions: length 9 x width 5 x height 8 meters or 9 x 5 x 5.

To obtain 1 ton of product, 2.5-3.5 m3 of raw material is used.

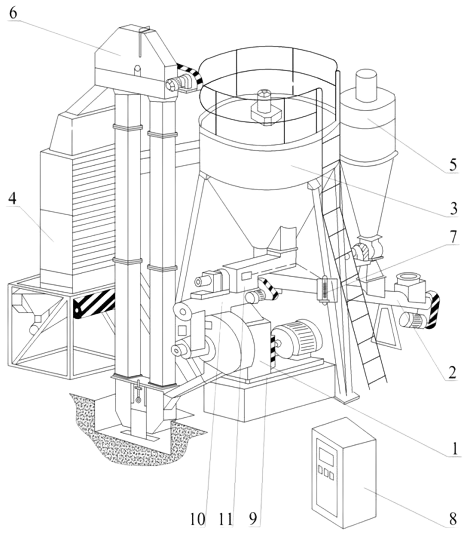

Operating principle of the OGM 1.5 pellet production line:

- The raw material prepared for granulation is fed by a screw feeder to the hopper, from where the raw material is fed evenly to the mixer. There it is moistened with water or steam to the required moisture content for granulation and intensively mixed.

- From the mixer, the wetted raw material is discharged through a ferromagnetic dirt separator into the granulator. In the press chamber, the raw material is pulled between the rotating die and rollers and forced through the die openings.

- The pellets squeezed out of the holes are cut to the required length by the cutters installed in the granulator. The length of the ground pellets can be adjusted by rotating the blade on its axis. The crushed pellets fall and are removed from the press by the housing sleeve.

- The pellets coming out of the press are hot and brittle. From the pelletizer, the pellets are transported to a cold storage facility. During cooling, excess moisture is extracted and the air blowing hardens the pellets, which are ready to be bagged after leaving the cooler.

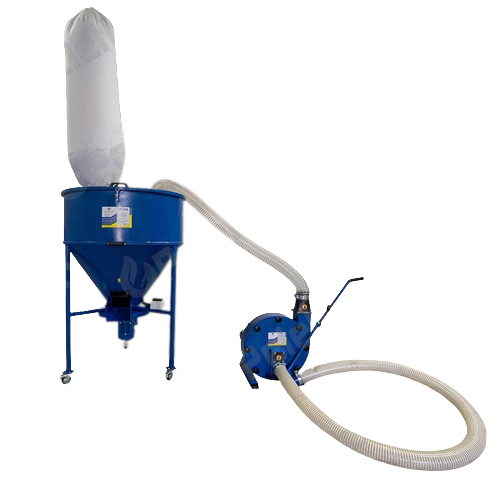

- From the cooler, the pellets go to sorting, where they are separated from the crumbs. The pellets are discharged from the outlet neck, and the crumbs are sucked into the cyclone, where they go with the raw material to be pelletized again.

It is possible to retrofit a pellet production line. Call and ask our specialists about it.

| № | Description | engine power | quantity | |||||

| 1. | Ring pelletizer OGM-1,5 including motor and rollers |

75 kW | 1 | |||||

| 2. | Mixer | 1.1 kW | 1 | |||||

| 3. | Dosing device | 2.2 kW | 1 | |||||

| 4. | Conveyor | 1.1 kW | 1 | |||||

| 5. | Resource | 2.2 kW | 1 | |||||

| 6. | Cyclone, pneumatic conveyor system | 18.5 kW | 3 | |||||

| 7. | Dosing feeder with geared motor | 2.2 kW | 3 | |||||

| 8. | Radiator conveyor | 1.5 kW | 2 | |||||

| 9. | cooling device | 1.1 kW | 1 | |||||

| 10. | Control cabinet | 1 | ||||||

| 11. | Matrix, country of origin: Italy | purchase in addition – ask | 0 | |||||

| 12. | semi-automatic packaging equipment – 2 kW | purchase additionally | 0 | |||||

| total price | PLN 300,000 net | |||||||

| № | AVM Dryer 0.65 | engine power | quantity |

| 1 | Loaded substrate, drying drum with auxiliary frame and drive | 3 kW | 1 |

| 2 | Active cyclone with pipeline | 18.5 kW | 1 |

| 3 | Sluice dispensers with a gearmotor | 3 kW | 1 |

| 4 | Automatic heat generator 1.2 MW with storage tank and automatic charging (furnace) | 3 kW | 1 |

| 5 | Control cabinet | 1 | |

| total price (net) | PLN 300,000 |

The content of this announcement is not a commercial offer under the Civil Code. To make a purchase, contact the merchant, confirm the price and delivery date.

***The amount may vary depending on the option selected. Prices do not include the fee for installation and transportation. For more details, call our specialist.

tel. 889 899 914

tel. 889 899 904