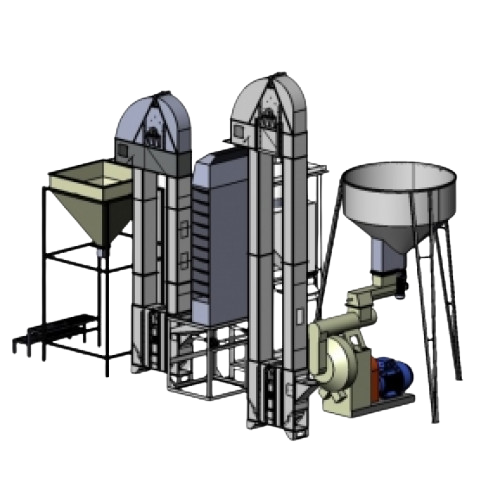

The MLP-150 mini-feed, compound feed production line from Peletto.co.uk with a capacity of up to 150 kg/h is a reliable and long-lasting complex that can perform perfectly on your farm.

The presented MLP-1000 line for feed production with a capacity of 1000 kg/h consists of a KRAFT-150 flail mill. Along with the shot blaster is the KC-300 which forms a line for producing feed from, among other things, grain waste. It also shreds grains, sunflower hulls, manure, feces. Sawdust loading is pneumatic.

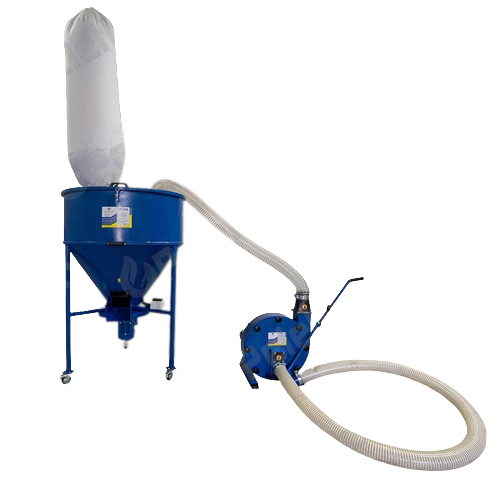

Peletto.co.uk offers to purchase a flail mill for sawdust processing, characterized by ease of operation. It is possible to quickly change screens with different hole diameters to adjust the degree of grinding. Crusher wear parts (screens, hammers) are always in stock.

The flail mill, grain blaster works as follows:

- The raw material is picked up by an ejector from a board, bunker or truck trailer. With the help of a suction pipe, it is directed to the crushing chamber;

- In the chamber, the raw material is crushed with rotary hammers and deflected on the screen walls until the size of the fraction is smaller than the size of the screen openings.

- The crushed raw materials are ejected through the screen into the housing by the hammer crusher under the influence of the air flow produced by the fan.

- The crumbled material is then directed to the fan chamber, from where it is transferred through an outlet pipe and a flexible pressure tube to the KC-300 horizontal mixer.

The shredder is useful for making animal feed, briquettes and pellets. It is ideal for both domestic and industrial households.

The grinder ensures even grinding of delivered raw materials with low formation of small dust-like fractions, and has the ability to adjust the degree of crushing.

The air inlet ejector provides convenience during operation, allows adjustment of air intake and prevents raw materials from clogging in the crusher during grinding.

The delivery of raw materials to the shredder is carried out by means of an ejector and PVC hoses included in the flail mill, eliminating the cost of purchasing, installing and maintaining transport equipment such as a conveyor.

Advantages of KRAFT-150 flail mill for grain, sawdust:

- Robust design;

- High Performance;

- It is suitable for grinding grains, corn cobs, shavings from carpenter sawdust;

- Overload protection;

The KC-300 feed mixer from Peletto.pl is designed for mixing bulk ingredients in feed production. To save money on regular purchases of feed mix for livestock: rabbits, birds or fish, it is better to buy a horizontal feed mixer. The mixer, with a tank capacity of 300 kg, is equipped with a 3 kW or 2.2 kW motor. Capacity is 1200 kg/h

Advantages of the feed mixer:

- Effective mixing is accomplished with a vertical auger that creates a continuous flow of product from the bottom to the top;

- The ingredients are fed into a feeding funnel placed at a convenient height, and the components can be fed during operation, saving mixing time;

- safety features and interlocks are available to ensure safe operation;

- In addition, you can buy a scale under the feed mixer to control the proportions;

- possible execution in stainless steel;

A given feed mixer has the following options for loading the mix:

- Upper;

- At the back from the loading opening, there are two 160 mm plugs in the lid, after removing one with a cyclone, you can feed raw material to the feed mixer from Peletto.co.uk;

- After removing the two plugs and pneumatically pumping the raw material through one and discharging air through the other into the filter or cyclone. In this method, there is a condition that loading should not be very fast.

The feed mixture obtained in the horizontal mixer can be further pelletized or used for other purposes. Buy good and effective equipment to prepare the right mix of feed, vitamins and mineral supplements yourself.

Feel free to check out our other ads posted on the Peletto website. Visit us at our demonstration hall in Poznań and see our entire machinery live. Give us a call, schedule a free consultation with one of our specialists, and choose your feed mix automation kit.

The content of this announcement is not a commercial offer under the Civil Code. To make a purchase, contact the merchant, confirm the price and delivery date.

tel. 889 899 914

tel. 889 899 904