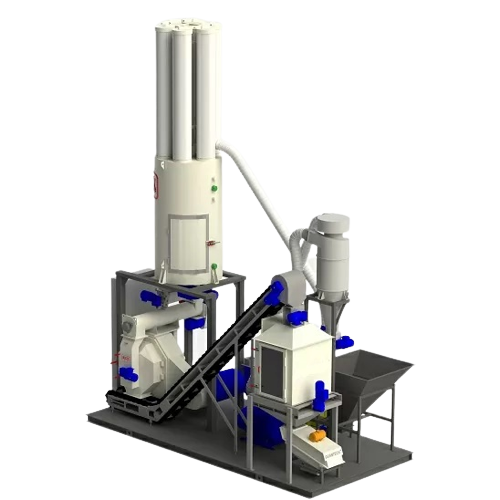

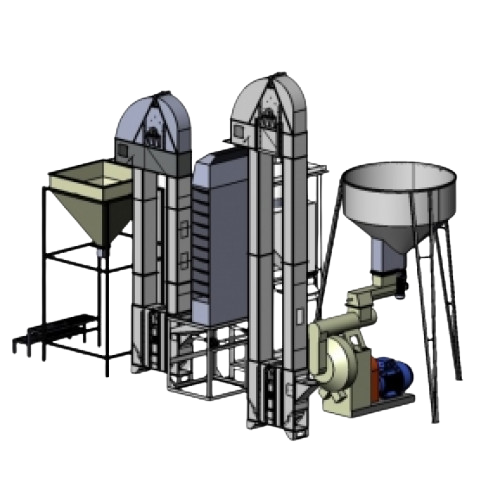

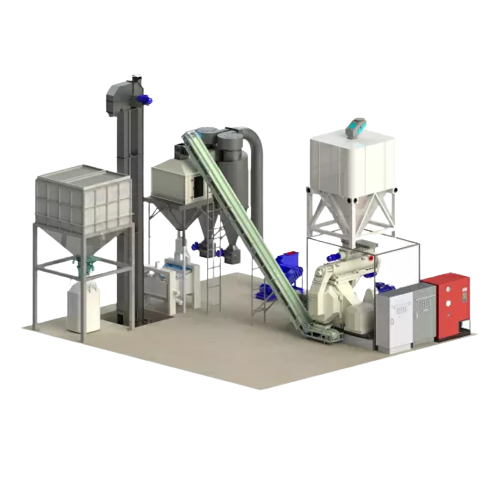

Mini complex, mini ring line GTL-304D is designed for the production of fuel pellets (pellets) from pre-prepared wood waste, grain straw, sunflower hulls and other energy biomass of plant origin.

- The capacity of the GTL-304D mini complex is from 0.5 t/h.

Mini granulation complex GTL-304 in its basic configuration consists of: receiving hopper, crusher with pneumatic loading, storage hopper, batcher, mixer, press-granulator GT-304D, belt conveyor with scrapers, cooler GTO-7×8, screen GTP-1, cyclone, fan, control system, filter unit.

| Press power, kW | 55 |

| Mixer power, kW | 3.0 |

| Dispenser power, kW | 0,75 |

| Stationary forced power, kW | 0,55 |

| Overall dimensions (W x L x H), mm | 1675x1650x1690 |

| Weight (kg | 1800 |

| Die diameter, mm | 304 |

| Die working width, mm | 55 |

| Number of rolls, pcs. | 2 |

| Diameter of rollers, mm | 142 |

Advantages of mini complex,,,, mini ring line:

- It is transported from the factory in an assembled state, and does not require assembly and disassembly during transportation.

- It is supplied with complete electrical installation of all equipment included in the mini complex.

- Ready to start work as soon as power is connected and raw materials are delivered.

- It is possible to move from place to place (to the center of the raw material base location) without large labor costs and downtime.

- No major assembly work is required, as it comes mounted on a frame with electrical wiring from the factory.

- Low energy consumption and operating costs.

- A good turnkey solution for a small business and a short payback period.

- The cost of organizing the production of mini-complexes is significantly lower than for lines of similar capacity.

- The mini complex is operated by a single operator.

To make the GTL-304D work, you need:

- 400 V, 50 Hz, 90 kW power supply.

- Compressed air at 4-6 atm. pressure, 250 l/min.

- Steam at 3 atm.

2 – drying zone for wet raw materials (drying complex GTSK-0, 6/4);

3 – the area of receiving, packaging and storage of finished products.

Call our representatives and ask for more!

The content of this announcement is not a commercial offer under the Civil Code. To make a purchase, contact the merchant, confirm the price and delivery date.

***The amount of PLN 0.00 is not the amount of the sale of the device.

tel. 889 899 914

tel. 889 899 904