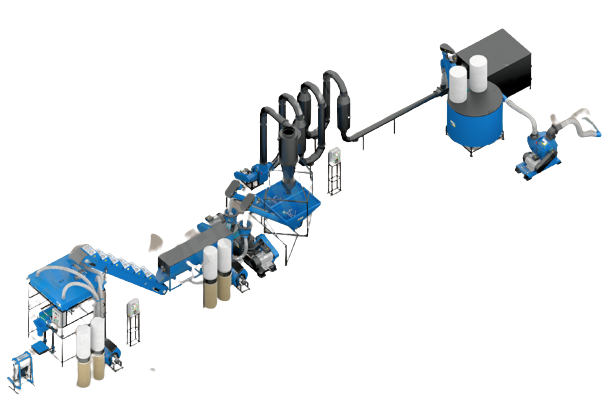

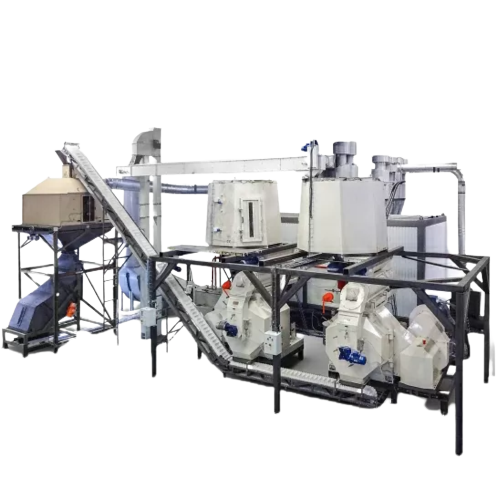

PELETON DUO MT is a line for producing pellets from wet sawdust. This is a complete line for producing pellets from wet sawdust or woodchips. Thanks to the high-quality workmanship of the machine, it guarantees longevity and a maximum output of up to 700-800 kg/h with relatively low energy consumption costs.

What goes into the complete PELETON 3000 DUO MT wet sawdust pellet line?

- LDG-3000 pellet production line

- SA-800 aerodynamic dryer

- Semi-automatic cooling and packaging system LH-1000

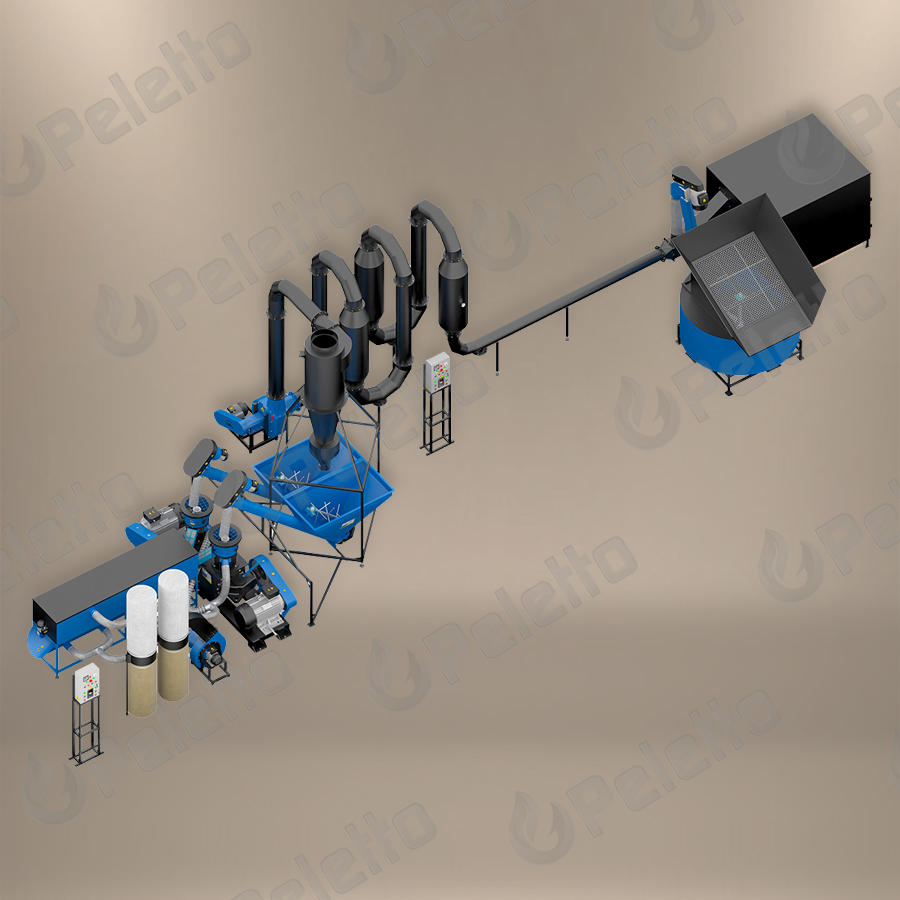

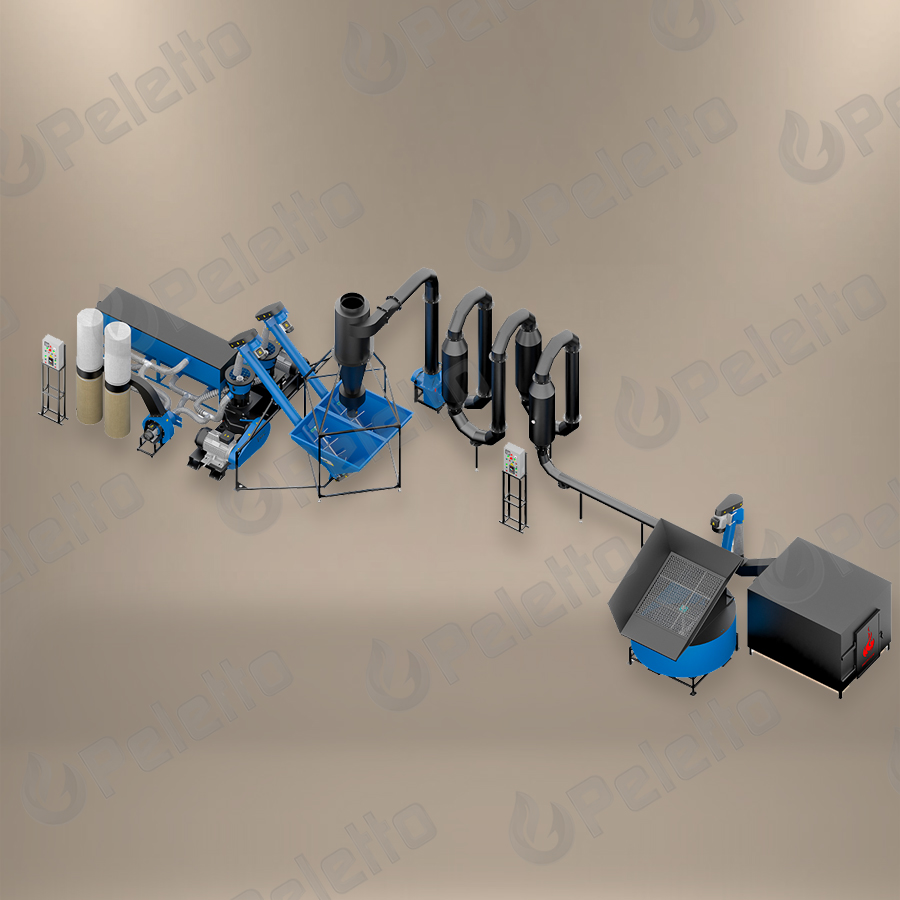

The production cycle of the wet sawdust pellet machine consists of several stages

- Raw material preparation stage. First, the raw material is prepared and crushed to the size of the appropriate fraction. The ideal fraction is considered 1 mm smaller than the diameter of the holes in the die. The wet crushed raw material is further transported to the SA-800 dryer where the product’s moisture content is brought to an ideal level, i.e. 12-15%. At the end of the dryer is a cyclone that separates the hot air along with the steam from the dried raw material.

- Pelletizing stage of raw material. From the cyclone, the dried raw material goes to the screw feeder. A feeder with an enlarged hopper and 2 adders has been designed specifically for the DUO index line. The feed speed of the raw material is controlled separately for each adder with a potentiometer. From the feeder, the product goes to the PELETON-300 pelletizer. The sawdust pelletizer of our production is designed to process hard raw materials such as sawdust from deciduous trees and coconut bark.

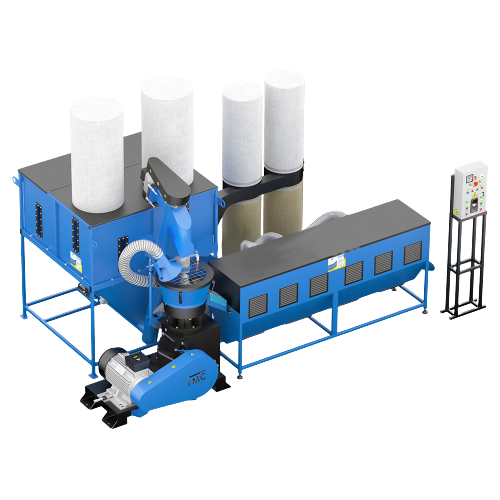

- Screening stage. The next production step of a complete wet sawdust pellet line is to screen the product. From the pelletizer, the pellets go to the calibration drum, where they are cooled with the help of air circulation. With the help of extraction, dust and non-separated particles go into dust collection bags. The dust from the bags can be reused in the pelletizing process.

- Cooling and packaging stage. The final step is cooling the pellets to a temperature at which the bags can be sealed. This is helped by the cooling and pellet packing complex. A conveyor belt with fans and an enclosed weighing-packing buffer with a connected extraction system, using circulation and air supply, cools the pellets to a temperature that allows them to be packed. The semi-automatic weigh-packing machine allows for quick and accurate loading of finished pellets.

We offer various types of complete production lines. We invite you to learn more about the other products that are posted on the site (click here and see other production lines, complexes, feed and pellet machines). Call our specialist and schedule a free consultation to select the perfect machine for your farm’s needs. Visit us in our demonstration hall in Poznan and see the work of our machines live.

The content of this announcement is not a commercial offer under the Civil Code. To make a purchase, contact the merchant, confirm the price and delivery date.

tel. 889 899 914

tel. 889 899 904