We present industrial feed granulation equipment with capacities up to 45 t/h. We will help design and start up the line and feeding systems, as well as separate technological equipment for granulation of raw material (biomass). Depending on requirements and technology, equipment can be selected for different types of farms specializing in cattle, pigs, poultry, fish, etc. The main purpose behind the production of this device is its operating time and ensuring the quality indicators of feed pellets at the output.

Raw materials for granulation: finished compound feed components, premixes, as well as mill waste (bran) and other agricultural feed waste.

- Capacity: from 1.0 to 45 t/h.

- The price is for a line with a capacity of 1 t/h

Our specialists will provide an individual approach to each client and will be happy to help develop technology that takes into account all the characteristics of the client’s enterprise, and will select equipment based on the technical task and the client’s wishes.

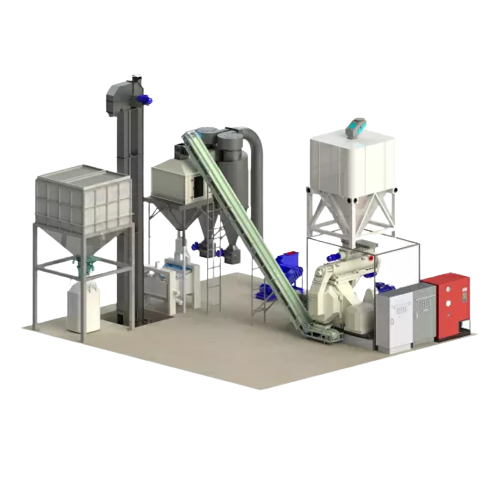

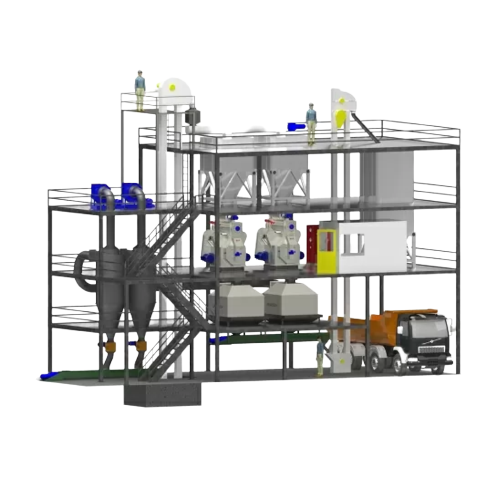

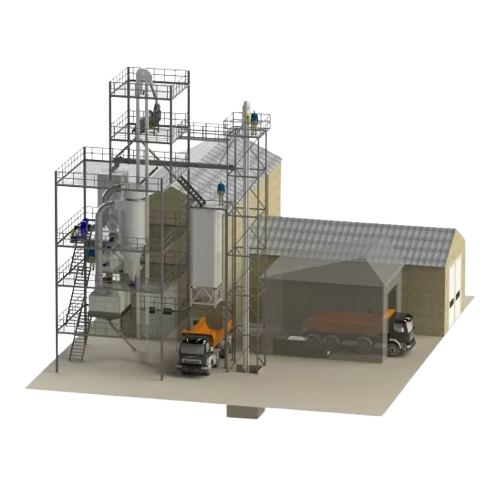

Installations (complete lines) for the production of compound feeds usually include:

1 – acquisition and metastasis region;

2 – storage area;

3 – dispensing area;

4 – grinding section;

5 – mixing zone;

6 – granulation area;

7 – composition of finished products.

Special corrosion-resistant materials are used in the manufacture of the equipment, which in turn guarantees the durability of the equipment and the maintenance of the quality indicators of the granules.

Turnkey compound feed installation is a chance to start a feed business without overpayments and wasted time. Specialists will take into account the features of the premises, the planned operation of the equipment, the availability and distribution of communications, as well as other nuances important in planning a feed plant.

Installation, production complex, feed factory: types of equipment and features

In fact, representatives of the agricultural industry, who are faced with the problem of disruption in the supply of feed, the constant increase in their costs and the decline in quality, which significantly affects their business, are increasingly making this decision. An in-house compound feed plant will eliminate these and similar problems and help significantly increase the company’s productivity while reducing production costs.

Mixed-feed facilities cover different areas of production:

- granulation area (includes equipment for the production of feed pellets);

- plot of loose compound feed (includes equipment of Khorolsky fur factory)

The equipment allows the preparation of feed mixtures of different compositions.

Why make fodder?

There are several options for using feed mills:

- for use – to feed animals and poultry on farms;

- For profit – the production and sale of feed.

Modern mixed feed plants are equipped with computerized control systems to reduce the cost of human resources and ensure independent operation of equipment. We manufacture and offer various types of equipment in different equipment options and configurations.

When selecting the optimal equipment for compound feed plants to meet all customer requirements, the specialists of the company group take into account the specifics of the equipment’s operation and the specifics of the raw materials used. processed.

Compound feed plant: specifics of product manufacturing

How does compound feed equipment work? The nuances of operation vary depending on the type of unit, but in general the technology has similar stages. The grain components are placed in a crusher, where they are crushed into the desired fraction. In addition, the GTIS straw shredder can be used to grind hay, grass and other leafy products.

The prepared ingredients go to the mixer, where they are mixed until a homogeneous mass is obtained. At this stage, the bulk feed mixture is fed into the dispensers, and the semi-finished product after granulation is directed for further processing. The granules are cooled and sieved to remove small particles and dust.

The GTI pellet crusher can also be used to grind pellets into pellets of a preset size.

The finished product is packaged for further use, storage or sale.

Feed mills

The most cost-effective solution will be not only to choose a compound feed plant and purchase it, but also to order a turnkey production line connection. In addition, we provide other services:

- Sales of components and spare parts for equipment, making it possible to replace worn parts in the shortest possible time;

- Ensure uninterrupted operation of equipment, prevention and maintenance of feed mills, production lines;

- Individual development of technological solutions taking into account the specifics of each enterprise.

The facilities of the compounding plant are EU-certified, confirmed by relevant international documents. The equipment attracts with its resistance to external factors, which allows to achieve:

- Extension of the operational period;

- Improving the quality of equipment;

- obtaining high-level fodder.

Feed mills are practical solutions for a price that is shaped individually and can change depending on the requirements for the equipment.

Call our representatives and ask for more!

The content of this announcement is not a commercial offer under the Civil Code. To make a purchase, contact the merchant, confirm the price and delivery date.