We present modern solutions for the feed and fuel pellet industry. Innovative lines, whole complexes for granular production. Gas is getting more expensive every year, and biofuel pellets (pellets) are being used as an alternative fuel, hence the popularity of fuel pellets continues to grow. At the same time, the production of this form of fuel of truly high quality requires not only raw materials, but also proven pellet equipment that works like clockwork.

- Capacity: from 0.5 to 12 t/h

- The price is for a line with a capacity of 1.5 t/h with a dryer and a woodchip shredder

The organization of granular biofuel production is divided into the following stages:

- pre-design work,

- Design,

- Assembly,

- equipment manufacturing and delivery;

- Construction works; installation and commissioning works.

- wood waste,

- energy willow,

- grain straw,

- sunflower husk,

- buckwheat groats,

- corn stalks,

- roso millet,

- lignin,

- peat

- other energy biomass.

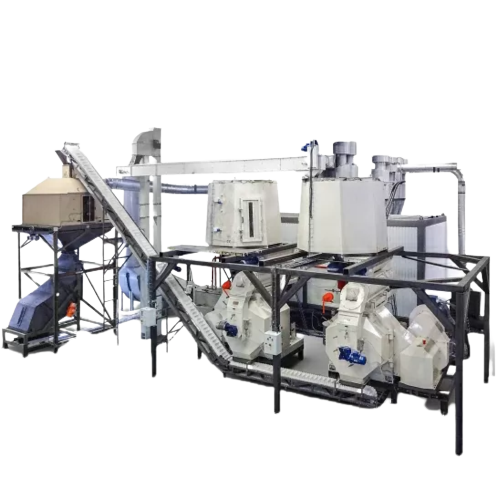

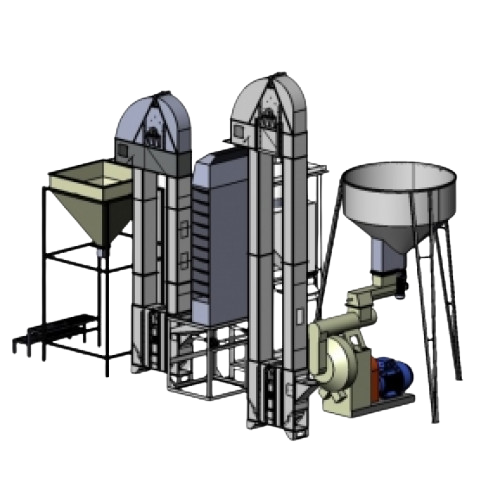

What elements are included in complete pellet production lines?

1 – composition of raw materials:

a – agricultural biomass waste;

b – wood waste;

2 – grinding area:

a – agricultural biomass waste;

b – wood waste;

3 – wet drying zone of raw material;

4 – granulation, cooling, screening section;

5 – accounting area, packaging of finished products;

Depending on the type of granulated raw material and its moisture content, granulation technologies vary.

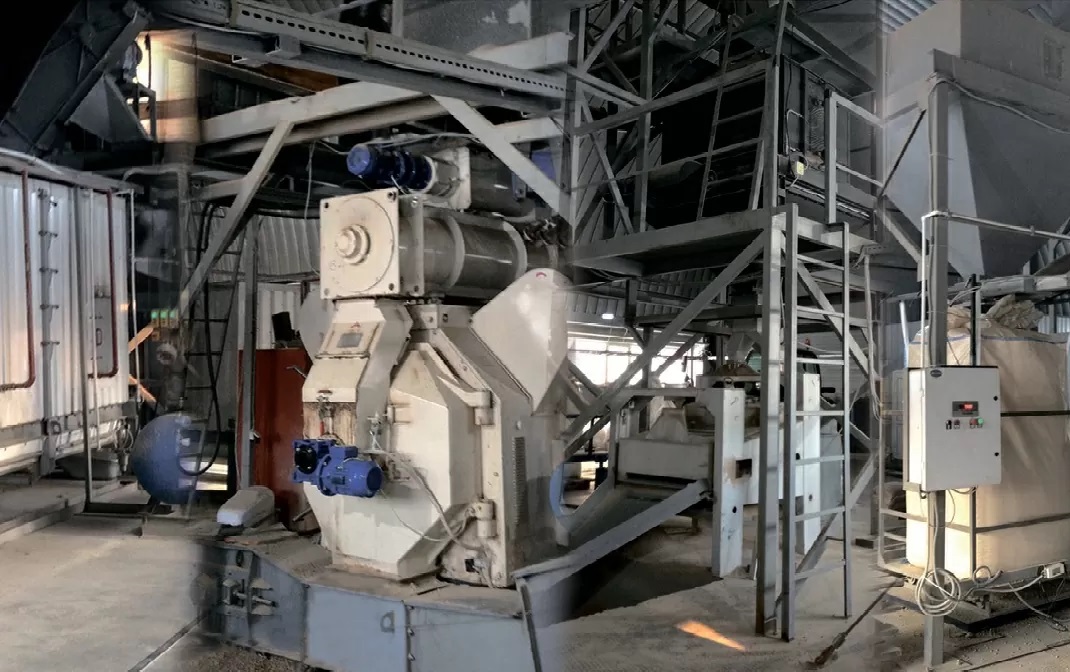

Pellet production on modern complexes

In order to create an efficient solid biofuel production that meets all international standards and requirements, several elements must be taken into account:

- carry out a high-quality design (develop technological solutions, layout drawings, select the necessary equipment that, according to its characteristics, will meet the requirements and ensure the expected productivity and quality of the final product);

- Provide raw materials of consistent quality;

- Select qualified service personnel or secure reliable service support from a major equipment supplier.

Biofuel production

At present, the concept of full-cycle engineering, or the concept of a turnkey pellet factory, is very important. At the same time, due to the lack of a sufficient number of qualified and reliable companies on the market, it is necessary to focus the implementation of the project work as much as possible on companies with practical experience, both in the creation of the biofuel production itself and in the operation of the equipment. Thus, for successful implementation of a pellet production project, one general contractor is needed who: understands exactly what pellet production technology the customer should have, manufactures and operates the equipment, provides service, and has the necessary licenses and certifications.

We take all these requirements into account. For more than 29 years, the specialists of the group of companies have been successfully implementing pellet installations for granulation of various products in such industries as oil and fat, alcohol, biofuels, etc.

Pellet line

In order to organize the efficient operation of a pellet pellet line, it is first necessary to understand the available quantities of raw materials, the desired capacity, the location of the future enterprise, the infrastructure (availability of engineering networks, buildings, production facilities), etc.

Since many factors determine how efficiently a pellet plant will operate in the future, our specialists first formulate a technical task together with the customer, which determines all the features of future production.

There are cases when the customer completely gave up on the idea of organizing biofuel production, receiving the results of basic engineering that clearly showed that pellet production under such conditions and quantities would never be profitable.

Raw material for granulation

The characteristics of the raw materials directly affect the type of equipment to be used. First of all, you need to know what kind of raw material it is: soft or hard rock, any fraction, moisture content, presence of impurities (sand, stones, metal chips). Depending on the characteristics and the amount of raw material available, specialists offer customers the optimal solution, it can be either a mini-pellet line with a capacity of 0.25 t/h, or a full-fledged pellet plant with a capacity of 5 t/h. above

In order to select the optimal granulation equipment and to be sure of the final product, the specialists of our fimry offer customers experimental granulation of raw materials. Based on the study, our specialists will offer the necessary equipment and its arrangement, select the optimal parameters of the working-matrix-roll pair for effective granulation. Currently, ICK Group specialists have developed more than 60 granulation technologies for various products.

Call our representatives and ask for more!

The content of this announcement is not a commercial offer under the Civil Code. To make a purchase, contact the merchant, confirm the price and delivery date.

***The amount of PLN 0.00 is not the amount of the sale of the device.

tel. 889 899 914

tel. 889 899 904