What is the LDG-3000 pellet production line designed for?

LDG-3000 pellet production line from the company

Peletto.pl

, is designed to produce pellets from various types of raw materials with a diameter of 2 mm to 8 mm. This unit differs from the LDG-2000 pelletizing line in that it has a more powerful pelletizer installed on the equipment.

Our dies, rollers, spare parts are made in Poland! Also, the cabinets and all the electrics are top of the line, also made in Poland while most of our competitors use Chinese cheap and unreliable substitutes! We focus on quality from the very beginning. Don’t skimp on security and bet on long-term cooperation with us.

The LDG-3000 granulation line is equipped with:

- PS-200 auger feeder: the device consumes 1.5 kW of electricity, and has stepless adjustment of auger speed by means of a frequency converter.

- Humidification system: the main components of the humidification system are an electro-valve, a pump, a 200-liter water tank and a timer. This system is connected to the screw feeder, allowing the necessary amount of water to be added to the pelletizer. Power consumption 0.37 kW.

- Robust pelletizer PELETON-300: PELETON-300 easily handles a variety of raw materials with a capacity of up to 350-400 kg/h for pellets and up to 400-500 kg/h for compound feed. 22 kW (1450 rpm) motor. Rotation reduced by the gearbox (all flooded with oil), which helps cool the entire system and protects against overheating and excessive wear. Such a machine can work in two shifts.

- Calibration and cooling drum for finished pellets PB-100: this device performs the function of screening pellets, which allows to obtain a clean final product (without dust and fines). The drum is connected to the extraction system. In addition, it is used to cool the pellets. Power consumption 0.12 kW.

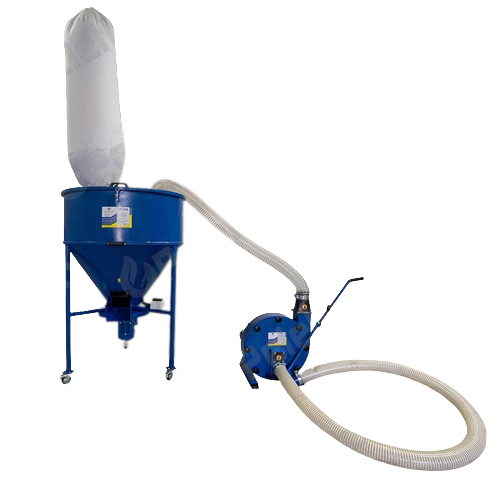

- Closed extraction system SO-315: this device consists of a fan, pipes for air flow and bags for dust filtration. Extraction provides the air circulation needed to cool granules, catching unspeculated particles and dust in bags. It is connected to the pelletizer head and the screening drum. Power consumption 1.5 kW.

- Pelletizing line control panel: this is a control cabinet with an automatic cooling system built into it. In addition, there is an amperometer for monitoring the load of the pelletizer and a button for emergency shutdown of the line. The controls are convenient as well as intuitive.

The most important thing is an expertly selected matrix and adherence to the fraction and moisture content requirements of the processed materials.

The pellet production line can be used as a separate production unit or equipped with additional equipment to automate the operation.

- The LDG-3000 granulation line can be equipped with the following components:

- TLK-200 (conveyor-calibrator), the main task is the delivery and calibration of raw materials;

- PT-500 (conveyor belt), the main task is the delivery and cooling of raw materials;

- RD-500 (shredder), the main task is to reduce the biomass fraction;

- MT-500 (sawdust mill, beater mill) – is used to grind sawdust and woodchips into a uniform fraction;

- SA-400 (aerodynamic dryer) – the main task is calibration and drying of raw materials.

We offer various types of complete production lines. We invite you to learn more about the other products that are posted on the site (click here and see other production lines, complexes, feed and pellet machines). Call our specialist and schedule a free consultation to select the perfect machine for your farm’s needs. Visit us in our demonstration hall in Poznan and see the work of our machines live. You can take your own raw material with you and test it.

The content of this announcement is not a commercial offer under the Civil Code. To make a purchase, contact the merchant, confirm the price and delivery date.

tel. 889 899 914

tel. 889 899 904