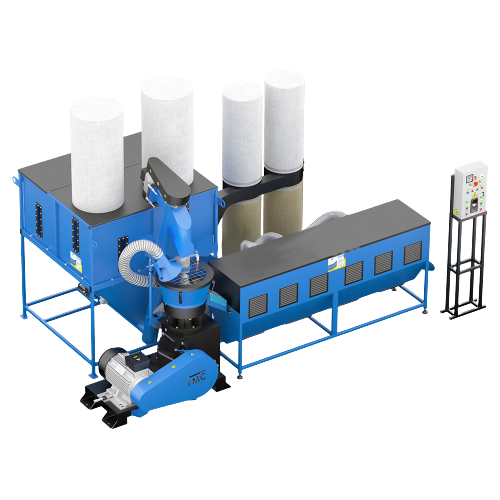

We present the highly efficient LDG-4000 line for pellet and pelleted feed production. It differs from the regular LDg-400 line in that it is equipped with a powerful 1.5 m3 PS-1500 screw feeder with a dust collection system. The line shown produces fuel pellets of 6 – 8 mm in size, and is great for producing pellets from straw, or other biomass. It is one of the larger single lines with a flat matrix.

Our dies, rollers, spare parts are made in Poland! Also, the cabinets and all the electrics are top of the line, also made in Poland while most of our competitors use Chinese cheap and unreliable substitutes! We focus on quality from the very beginning. Don’t skimp on security and bet on long-term cooperation with us.

The complete LDG-4000 pellet production line consists of the following components:

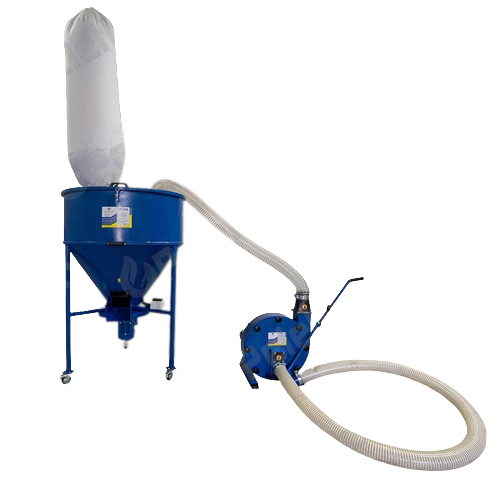

- PS-1500 screw feeder: the device consumes 2.6 kW of electricity and acts as a cyclone. The main task of the PS-1500 is to mix the raw material for further feeding into the pelletizer. The capacity of the tank is 1.5 m3.

- Humidification system: the main components of the humidification system are an electro-valve, a pump, a 200-liter water tank and a timer. This system is connected to the screw feeder, allowing the necessary amount of water to be added to the pelletizer. Power consumption 0.37 kW.

- PELETON-400 pelletizer: consumes 37 kW of power. This is the largest flat die pelletizer of our production. The movable rollers (148 mm high, 118 mm wide) installed in this machine are designed to cover as many working holes on the die (400 mm) as possible.

- Extended calibration and cooling drum for finished pellets PB-200: this device performs the function of screening pellets, which allows to obtain a clean final product (without dust and fines). The drum is connected to the extraction system. In addition, it is used to cool the pellets. The extended drum was designed specifically for this line. Power consumption 0.12 kW.

- Closed extraction system SO-315: this device consists of a fan, pipes for air flow and bags for dust filtration. Extraction provides the air circulation needed to cool granules, catching unspeculated particles and dust in bags. It is connected to the pelletizer head and the screening drum. Power consumption 1.5 kW.

- Pelletizing line control panel: this is a control cabinet with an automatic cooling system built into it. In addition, there is an amperometer for monitoring the load of the pelletizer, and a button for emergency shutdown of the line. The controls are convenient as well as intuitive.

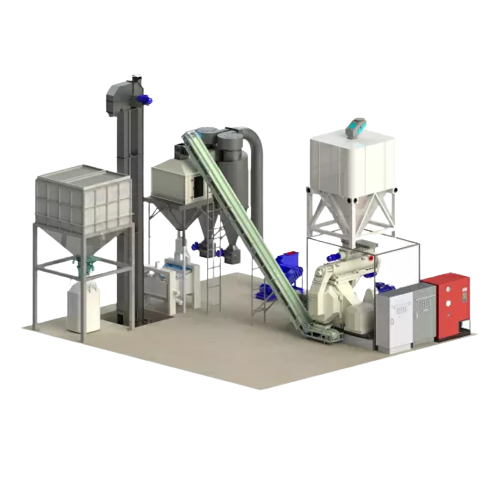

- TLK-200 (conveyor-calibrator), the main task is the delivery and calibration of raw materials;

- PT-500 (conveyor belt), the main task is the delivery and cooling of raw materials;

- RD-500 (shredder), the main task is to reduce the biomass fraction;

- MT-500 (sawdust mill, beater mill) – is used to grind sawdust and woodchips into a uniform fraction;

- SA-600 (aerodynamic dryer) – the main task is calibration and drying of raw materials.