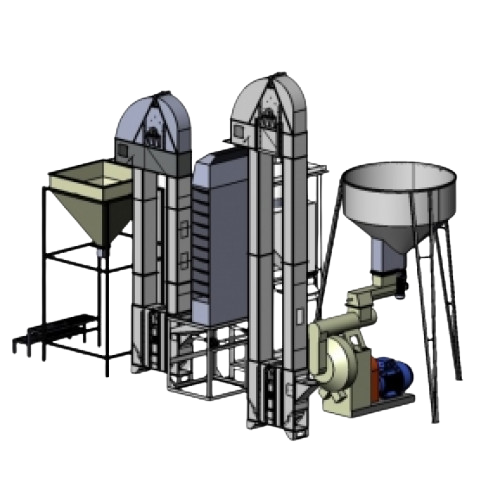

PELETON-3000 S is a modern, high-quality and reliable machine, a straw pellet line with a required moisture content of 12-15%. The capacity of the pellet line reaches 330-480 kg/h.

Composition of straw pellet machine with a capacity of up to 350 kg/h:

- LDG-3000 pellet production line

- Shredder RD-500 with cyclone

- Belt conveyor PT-1000 with fans

The PELETON-3000 S straw pellet machine is equipped with:

- Shredder RD-500: The initial stage of straw preparation in the straw pellet machine is the shredding of bales and cubes in the chopper. A bale crusher is a crusher with a large circular chamber in which a rotor cuts bales and cubes, bringing the raw material to a uniform fraction suitable for further pelleting.

- PS-200 screw feeder: The raw material is fed into the pelletizer by a screw feeder beforehand passing through a bunker that prevents the material from clumping. The unit has a dispenser that feeds straw evenly into the pelletizer head. In most cases, the straw used for pelleting is too dry, so it should be moistened to an appropriate level of 12-15%. The line also includes an injection humidification system, which will easily raise the humidity to the desired level.

- PELETON-300 Pelletizer: PELETON series pelletizer with movable rollers and suitable matrix can easily handle biomass processing. The matrix and rollers are heated to 80-100 °С, which allows to separate the lignin contained in the straw. Lignin plays an important role in the production process using a straw pellet machine.

- PB-100 sifter/cooler: hot pellets are delivered directly to the cooler. In the column, it is blown by cool air, which causes the pellet to harden. Small non-grainy particles are separated by a sieve and extracted into dust collection bags.

- Bagging: After cooling, the product is delivered by conveyor belt to either a big bag or a weigh-packing machine. The conveyor also cools the pellets using fans. The semi-automatic weigh-packing machine is equipped with a scale that measures the required amount of pellets. The additional installation of a foot pedal in the machine makes work much easier.

- Extraction SO-315: It is necessary to have a system of extraction and air ducts so that fine dust particles do not enter the air and settle in the room. Therefore, our straw pellet machine is also designed to filter dust from the air and deposit it in bags.

We offer various types of complete straw pellet machines. We invite you to learn more about the other products that are posted on the site (click here and see other production lines, complexes, feed and pellet machines). Call our specialist and schedule a free consultation to select a straw pellet machine perfectly suited to your farm’s needs. Visit us in our demonstration hall in Poznan and see the work of our machines live.

The content of this announcement is not a commercial offer under the Civil Code. To make a purchase, contact the merchant, confirm the price and delivery date.

tel. 889 899 914

tel. 889 899 904