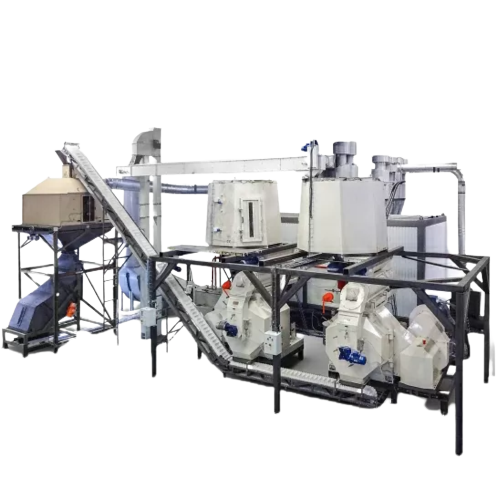

The complete PELETON-3000 ZR line with a capacity of 350-400 kg/h is ideal for producing pellets from materials such as branches, wood chips. In addition, to meet customer needs, we offer you the possibility of installing a weigh-packing machine at the end of the line, which will further facilitate and improve the production process on your farm.

Our dies, rollers, spare parts are made in Poland! Also, the cabinets and all the electrics are top of the line, also made in Poland while most of our competitors use Chinese cheap and unreliable substitutes! We focus on quality from the very beginning. Don’t skimp on security and bet on long-term cooperation with us.

Of which consists of this wet woodchip pellet production line?

- LDG-3000 pellet production line

- SA-400 aerodynamic dryer

- MT-500 flail mill with cyclone

- RK-600 chipper

Production stages of the PELETON-3000 ZR woodchip pellet production line:

- Branches should be chipped into woodchip. The RK-600 with an 11kW electric motor is used for this. There is also an option to equip with a combustion engine or adapt to a tractor PTO;

- For pellet production, the woodchip is too large so it should be shredded to a fraction of 5-6 mm. Shredding is carried out using an MT-500 beater mill with a 22kW electric motor. From the flail mill, the crushed raw material goes to the feeder in the dryer. The screw feeder is equipped with a large 1.5m3 bunker and dust collection bags, which helps separate the raw material from the air;

- The next step is to dry the raw material. With the help of a feeder, the raw material goes to an aerodynamic dryer where the moisture content reaches 12-15%;

- Further prepared raw material is fed to the PELETON-300 series pelletizer, where the pelletizing process takes place. Our pelletizers are specially designed for processing leaf sawdust, coniferous sawdust and other hard raw materials;

- The finished pellet goes into the drum of the sifter, where it is sifted and separated from dust, dirt and other fines. In addition, the pellets are cooled using air vents;

- At the end of the woodchip pellet production line is the option of installing a weigh-packing machine.

The capacity of the whole complex is 350-400kg/h of already finished pellets!

We offer various types of complete production lines. We invite you to learn more about the other products that are posted on the site (click here and see other production lines, complexes, feed and pellet machines). Call our specialist and schedule a free consultation to select the perfect machine for your farm’s needs. Visit us in our demonstration hall in Poznan and see the work of our machines live.

*Prices are given in net, 23% VAT should be added to them.

The content of this announcement is for information purposes only and does not constitute a commercial offer within the meaning of the Civil Code and other laws. The content of this announcement is not a commercial offer under the Civil Code. To make a purchase, contact the merchant, confirm the price and delivery date.

tel. 889 899 914

tel. 889 899 904