The Peletto company provides consulting services and the making of consumables for pellet machines, namely. dies, complete rolls, and roll coats. Interested parties are welcome to contact the customer service department. We are a manufacturer, not just a supplier through which we offer technical support and expert advice in the selection of the matrix.

Our company uses d0 forgings to manufacture ring dies exclusively from German 46Cr13 grade stainless steel. Such steel is characterized by the composition of the right amount of carbon, chromium, nickel, manganese and vanadium, which makes it possible to produce a ring die with a high shelf life. Some of our customers have worked 1500-2000 tons on our ring dies.

Continuous testing of the ring die at each stage of production, allows to obtain a final product free of defects. The hardening process is the most important stage because the mechanical strength of the dies depends on it. The desired high hardness characteristics are achieved using hardening furnaces. Heat treatment of ring dies performed in a nitrogen atmosphere in technological vacuum furnaces. We use the technique of martensitic hardening – it is a heat treatment that allows to obtain high hardness and strength of steel. Includes austenitizing, rapid cooling and tempering to preserve the structure of tempered martensite or bainite.

Such a heat treatment process makes it possible to obtain excellent hardness at the level of (52-54 HRC), flatness on the entire surface and smoothness of the compression cones. For this reason, our dies are designed for 24H/day continuous operation and serve for a longer period of time, reducing production costs.

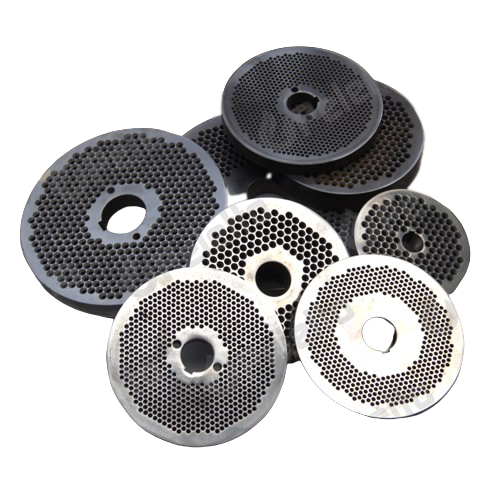

Production of ring dies by Peletto.co.uk

- Our dies are manufactured with the highest precision machining and are hardened in modern and efficient vacuum furnaces;

- Repeatability of the highest quality is the most important feature that guarantees production and labor safety for our customers;

- Ring dies are drilled with barrel drills, this allows you to get smooth holes and inlet cones, such dies do not need special lapping;

- CNC milling machines of the latest generation make it possible to achieve an optimal distribution of holes, depending on the granulated raw material;

- Internal diameter from 250 mm and up to 1000 mm;

- Openings from 2 to 12 mm;

Production of our rollers and wear parts for ring pelecia machines:

- We manufacture complete rollers and roller coats (runners) for the following Peleciarek brands: LaMeccanica, Buhler, Munch, VanAarsen, Promill-Stolz, Andritz, Kahl, Salmatec, Mabrik, CPM, PTN, DMT, Nawrocki TG, Testmer;

- We advise on selecting the optimal tread working width for the power and inner diameter of the die;

- We manufacture complete rollers, roller coats and a full range of accessories: covers, shafts (eccentrics), seals;

We provide the price by phone: +48 537 134 390, +48 732 917 962 or send a request with contact information in the message and our consultant will contact you shortly.

We sincerely believe that this information may be useful to you and will form the basis for our continued mutually beneficial cooperation.

The content of this announcement is for information purposes only and does not constitute a commercial offer within the meaning of the Civil Code and other laws. The content of this announcement is not a commercial offer under the Civil Code. To make a purchase, contact the merchant, confirm the price and delivery date.

tel. 889 899 914

tel. 889 899 904